14.4 tonne - Hitachi ZX 130 LCN-6 Excavator

HYDRAULIC EXCAVATOR

Model code : ZX130-6 / ZX130LCN-6

Engine rated power : 78.5 kW (ISO14396)

Operating weight : 13 400 – 15 700 kg

Bucket ISO heaped : 0.19 – 0.66 m³

The Hitachi ZX 130 LCN-6 Excavator is a 14.4 tonne (operating weight) tracked excavator which we offer on a self-drive or operated basis. For our up-to-date prices please call T:01482 319480. hiredesk@headlandplant.co.uk

The information below is provided by the manufacturer. This may vary depending on the year of the machine.

SPECIFICATIONS

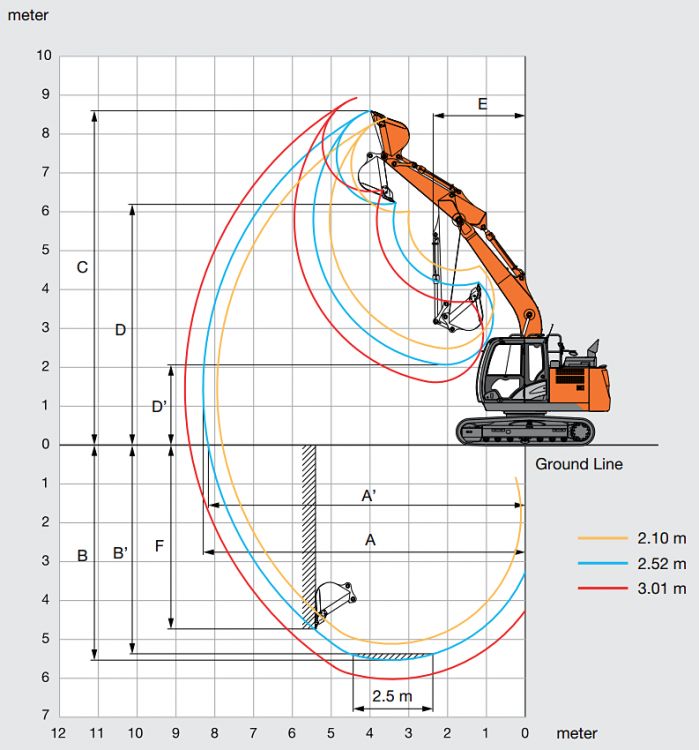

ZAXIS 130 / ZAXIS 130LCN - MONOBLOCK BOOM - WORKING RANGES:

| Unit: mm | |||

| Arm length | 2.10 m | 2.52 m | 3.01 m |

| A Max. digging reach | 7 940 | 8 300 | 8 770 |

| A’ Max. digging reach (on ground) | 7 800 | 8 170 | 8 650 |

| B Max. digging depth | 5 120 | 5 540 | 6 030 |

| B’ Max. digging depth for 2.5 m level | 4 870 | 5 310 | 5 840 |

| C Max. cutting height | 8 400 | 8 600 | 8 930 |

| D Max. dumping height | 5 990 | 6 190 | 6 520 |

| D’ Min. dumping height | 2 490 | 2 070 | 1 610 |

| E Min. swing radius | 2 350 | 2 400 | 2 620 |

| F Max. vertical wall digging depth | 4 450 | 4 750 | 5 220 |

| Excluding track shoe lug |

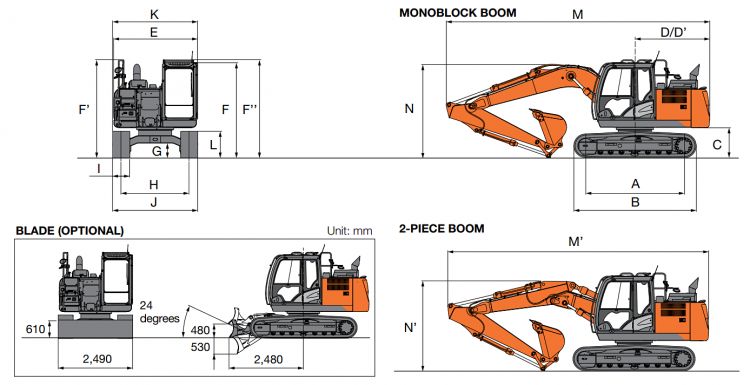

| Unit: mm | ||

| ZAXIS 130 | ZAXIS 130LCN | |

| A Distance between tumblers | 2 880 | 3 050 |

| B Undercarriage length | 3 580 | 3 750 |

| * C Counterweight clearance | 840 | 840 |

| D Rear-end swing radius | 2 190 | 2 190 |

| D’ Rear-end length | 2 190 | 2 190 |

| E Overall width of upperstructure | 2 460 | 2 460 |

| F Overall height of cab | 2 790 | 2 790 |

| F’ Overall height of handrail | 2 870 | 2 870 |

| F’’ Overall height of handrail (on cab) | 2 870 | 2 870 |

| * G Min. ground clearance | 410 | 410 |

| H Track gauge | 1 990 | 1 990 |

| I Track shoe width | G 500 | G 500 |

| J Undercarriage width | 2 490 | 2 490 |

| K Overall width | 2 490 | 2 490 |

| *1 L Track height with triple grouser shoes | 780 | 780 |

| MONOBLOCK BOOM | ||

| M Overall length | ||

| With arm 2.10 m | 7 700 | 7 700 |

| With arm 2.52 m | 7 700 | 7 700 |

| With arm 3.01 m | 7 710 | 7 710 |

| N Overall height of boom | ||

| With arm 2.10 m | 2 630 | 2 630 |

| With arm 2.52 m | 2 750 | 2 750 |

| *2 With arm 3.01 m | 2 740 | 2 740 |

SPECIFICATIONS

| ENGINE | |

| Model | Isuzu AR-4JJ1X |

| Type | 4-cycle water-cooled, common rail direct injection |

| Aspiration | Variable geometry turbocharged, intercooled, cooled EGR |

| Aftertreatment | DOC and SCR system |

| No. of cylinders | 4 |

| Rated power | |

| ISO 14396 | 78.5 kW at 2 000 min-1 |

| ISO 9249, net | 74.9 kW at 2 000 min-1 |

| SAE J1349, net | 74.9 kW at 2 000 min-1 |

| Maximum torque | 375 Nm at 1 800 min-1 |

| Piston displacement | 2.999 L |

| Bore and stroke | 95.4 mm x 104.9 mm |

| Batteries | 2 x 12 V / 58 Ah |

| HYDRAULIC SYSTEM | |

| Hydraulic Pumps | |

| Main pumps | 2 variable displacement axial piston pumps |

| Maximum oil flow | 2 x 117 L/min |

| Pilot pump | 1 gear pump |

| Maximum oil flow | 33.6 L/min |

| Hydraulic Motors | |

| Travel | 2 variable displacement axial piston motors |

| Swing | 1 axial piston motor |

| Relief Valve Settings | |

| Implement circuit | 34.3 MPa |

| Swing circuit | 32.3 MPa |

| Travel circuit | 34.3 MPa |

| Pilot circuit | 3.9 MPa |

| Power boost | 36.3 MPa |

| Hydraulic Cylinders | |||

| Quantity | Bore | Rod diameter | |

| Boom | 2 | 105 mm | 70 mm |

| Arm | 1 | 115 mm | 80 mm |

| Bucket | 1 | 100 mm | 70 mm |

| Positioning * | 1 | 140 mm | 95 mm |

| * : For 2-piece boom |

UPPERSTRUCTURE

Revolving Frame

D-section frame for resistance to deformation

Swing Device

Axial piston motor with planetary reduction gear is bathed in oil. Swing circle

is single-row. Swing parking brake is spring-set/hydraulic-released disc type.

Swing speed ................ 13.3 min-1

Swing torque ................ 34 kNm

Operator's Cab

Independent spacious cab, 1 005 mm wide by 1 675 mm high,

conforming to ISO* Standards.

* International Organization for Standardization

UNDERCARRIAGE

Tracks

Tractor-type undercarriage. Welded track frame using selected materials.

Side frame welded to track frame. Lubricated track rollers, idlers, and

sprockets with floating seals.

Track shoes with triple grousers made of induction-hardened rolled alloy.

Heat-treated connecting pins with dirt seals. Hydraulic (grease) track

adjusters with shock-absorbing recoil springs.

| Numbers of Rollers and Shoes on Each Side | |

| Upper rollers | 1 : ZAXIS 130 |

| 2 : ZAXIS 130LCN | |

| Lower rollers | 7 |

| Track shoes | 44 : ZAXIS 130 |

| 46 : ZAXIS 130LCN | |

| Track guard | 1 |

| Travel Device |

| Each track driven by 2-speed axial piston motor. Parking brake is spring-set/hydraulic-released disc type. Automatic transmission system: High-Low. |

| Travel speeds: High : 0 to 5.5 km/h |

| Low : 0 to 3.3 km/h |

Maximum traction

force ............................ 117 kN

Gradeability .................. 70% (35 degree) continuous

| SOUND LEVEL | |

| Sound level in cab according to ISO 6396 | LpA 69 dB(A) |

| External sound level according to ISO 6395 and EU Directive 2000/14/EC |

LwA 98 dB(A) |

| SERVICE REFILL CAPACITIES | |

| Fuel tank | 285.0 L |

| Engine coolant | 21.0 L |

| Engine oil | 17.0 L |

| Swing device | 3.2 L |

| Travel device (each side) | 4.2 L |

| Hydraulic system | 185.0 L |

| Hydraulic oil tank | 69.0 L |

| DEF/AdBlue® tank | 35.0 L |

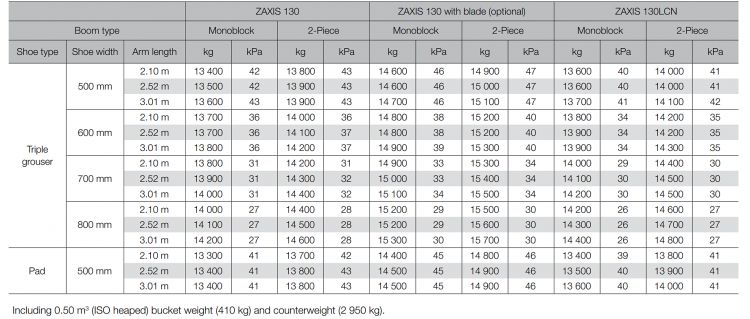

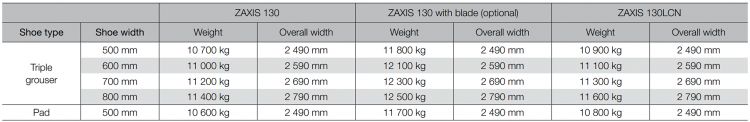

WEIGHTS AND GROUND PRESSURE

Operating Weight and Ground Pressure

Basic Machine Weight and Overall Width

Excluding front end attachment, fuel, hydraulic oil and

coolant etc. Including counterweight

Components Weight

| Weight | |

| Counterweight | 2 950 kg |

| Monoblock boom (with arm cylinder and boom cylinder) | 1 220 kg |

| 2-Piece boom (with arm cylinder and boom cylinder) | 1 600 kg |

| Arm 2.10 m (with bucket cylinder) | 550 kg |

| Arm 2.52 m (with bucket cylinder) | 600 kg |

| Arm 3.01 m (with bucket cylinder) | 670 kg |

| Bucket 0.50 m³ | 410 kg |

BUCKET AND ARM DIGGING FORCE - ZAXIS 130 / ZAXIS 130LCN

| Arm length | 2.10 m | 2.52 m | 3.01 m |

| Bucket digging force* ISO | 104 kN | 104 kN | 104 kN |

| Bucket digging force* SAE : PCSA | 91 kN | 91 kN | 91 kN |

| Arm crowd force* ISO | 77 kN | 69 kN | 61 kN |

| Arm crowd force* SAE : PCSA | 74 kN | 67 kN | 60 kN |

| * At power boost |

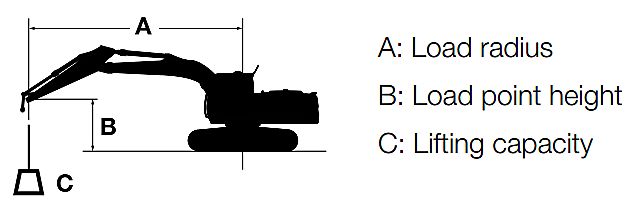

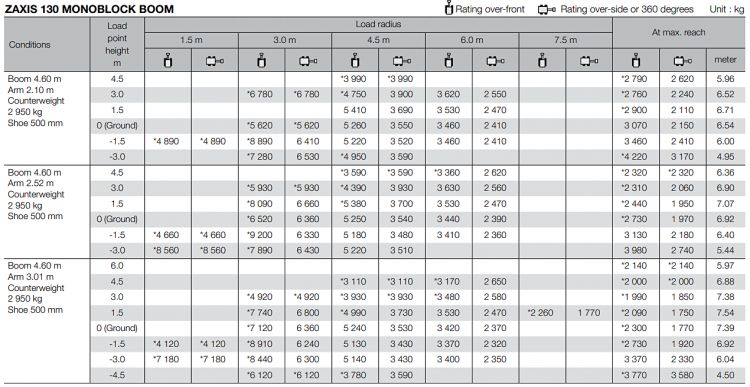

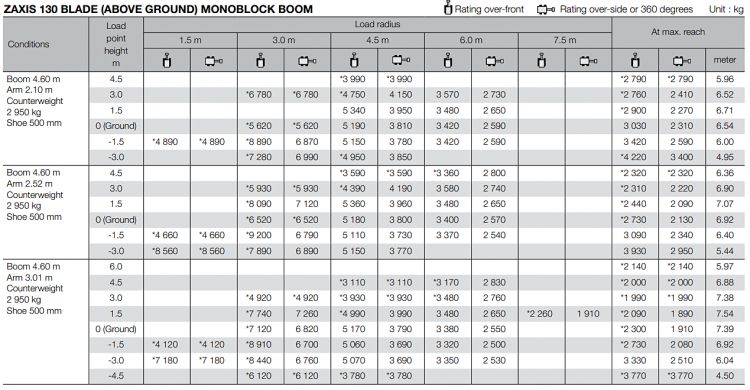

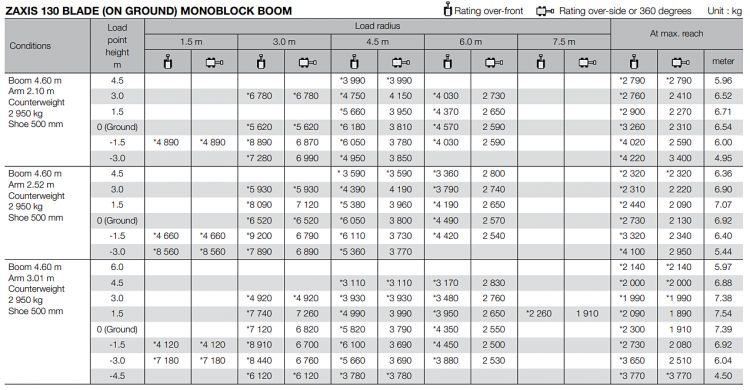

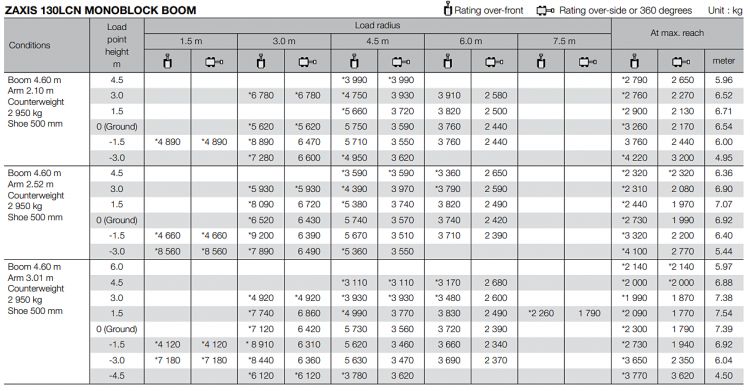

LIFTING CAPACITIES

Notes: 1. Ratings are based on ISO 10567.

2. Lifting capacity does not exceed 75% of tipping load with the machine on firm,

level ground or 87% full hydraulic capacity.

3. The load point is the center-line of the bucket pivot mounting pin on the arm.

4. *Indicates load limited by hydraulic capacity.

5. 0 m = Ground.

For lifting capacities, subtract bucket and quick hitch weight from lifting capacities.

ZX130-6.

NO COMPROMISE

The smallest model in the Zaxis-6 medium excavator range, the ZX130-6 benefits from the same Hitachi technology proven in the performance of the larger machines. Thanks to its Zaxis-6 heritage, it shares the same high quality of engineering and durable components, and offers exceptional levels of reliability.

The ZX130-6 is a user-friendly and versatile excavation machine. Available with a variety of options, it is suitable for a wide range of applications and can be made to meet your exact requirements.

DEMAND PERFECTION

From the world’s largest excavator factory comes the Hitachi ZX130-6 – designed and built for the specific needs of the European construction industry. Incorporating innovative technology, developed specifically for the Zaxis-6 range of medium excavators, it performs reliably and efficiently with the lowest possible cost of ownership.

Optimum performance

Remote monitoring with Global e-Service online application.

High quality

Only the best design elements and materials.

Incredible versatility

Tilt and rotary tilt modes complete the attachment support system.

Lifetime reliability

Reliable components help to prevent oil leaks.

Ultimate durability

Strengthened bushing material improves wear resistance.

User-friendly

Safety comes first with handrails and a reinforced safety platform.

Low emissions

SCR system reduces NOx from exhaust gas.

Low fuel consumption

7% fuel saving in PWR mode (5% in ECO mode).

Easy maintenance

Convenient and wide-opening engine cover.

Engine protection

High performance and large-capacity fuel circuit.

Excellent efficiency

HIOS IV reduces total hydraulic loss.

NON-STOP RELIABILITY

Like all Zaxis-6 medium excavators, the ZX130-6 is built to work reliably all day, every day. Always available to deliver a high level of performance and efficiency for a wide range of applications, it offers stress-free days on the job site – without interruptions or complications.

Easy maintenance

The engine cover can be conveniently opened up fully from the platform. This provides easy access to the engine compartment and other components for routine maintenance.

Durable hydraulic connection

A rubber hose fitted with a flange has been incorporated into the design of the hydraulic return pipes. These enhance the reliability of the system and reduce the risk of oil leaks.

User-friendly fuel filter

The main fuel filter screws into place on the ZX130-6. This makes it easier to replace and ensures that dust is prevented from entering the fuel circuit during routine maintenance procedures.

More efficient cooling

The expansion tank is mounted on top of the engine’s cooling system. This revised position means that the air can be completely removed and prevents the engine parts from overheating.

Hitachi excavators are tested extensively in job site conditions on Hokkaido, the second largest and northernmost Japanese island, in temperatures ranging from -25°C to 35°C.

FIRST FOR DURABILITY

The Zaxis-6 range of medium excavators is continuing the Hitachi reputation for market-leading reliability and durability. The ZX130-6 is the result of decades of manufacturing experience and tough testing procedures, and is designed and engineered to ensure a reliable operation, even in challenging environments.

Strengthened materials

A new wear-resistant bushing material on the upper roller improves durability and reliability of the ZX130-6.

Enhanced fuel circuit

A high performance water separator and cold fuel resistance valve are integrated into the pre-filter for added protection against moisture. In addition, a large capacity electric fuel pump supplies an appropriate amount of fuel to the engine for an improved performance.

Engine protection

The combustion chamber is made from stronger materials and the revised shape of the piston is designed to achieve cleaner emissions. These features will further enhance the reliability of the engine.

Reinforced platform

The covers on the platform walkway have been reinforced. This adds to the high-quality and safe working environment, which provides peace of mind for the operator.

EXCEPTIONAL VERSATILITY

The ZX130-6 is a popular choice for a wide range of construction applications because it is easy to use and extremely versatile. It can be built to meet the requirements of a particular job site, thanks to a variety of optional extras. Wherever it operates, the Zaxis-6 excavator provides a smooth, fast and precise performance.

Greater flexibility

The engine cover can be conveniently opened up fully from the platform. This provides easy access to the engine compartment and other components for routine maintenance.

Power boost

The tried-and-tested power-boost feature has 10% more capacity than the ZX130-3. This increases the capability of the ZX130-6 to deliver an enhanced level of excavating performance and lifting power.

User-friendly

An optional pilot accumulator allows for the pressure in the attachment circuit to be lowered after the engine has stopped. This ensures the safe and easy replacement of attachments.

Improved control

The ZX130-6 can be equipped with an optional auxiliary function lever, which has a proportional switch that allows for greater control of the attachment and a precise operation.

Comments from customers and Hitachi personnel are reported at monthly product improvement meetings, held at Tsuchiura Works in Japan, to help maintain quality standards.

SUPERIOR QUALITY

Quality is a top priority at Hitachi’s factories in Japan, where every model is rigorously tested to ensure the highest possible standards of reliability and safety.

The ZX130-6 has been developed using the same high-quality components and materials as the larger Zaxis-6 medium excavators to provide a superior performance.

Superior cooling performance

The upper structure benefits from high-quality sealant (around the cooling package) and acoustic materials to eliminate any deterioration caused by heat. These ensure the long-term cooling and low-noise acoustic performance of the ZX130-6.

Excellent weather resistance

The cab console has been sculpted in highly durable AES-grade resin. This ensures superior weather resistance and ultimately prevents the sun’s ultraviolet rays from damaging the console.

Reduced emissions

Hitachi has developed a selective catalytic reduction (SCR) system that injects urea into exhaust gas to reduce nitrogen oxide from emissions. This cutting-edge technology not only helps the environment, but also complies with EU Stage IV emission regulations.

Ultimate comfort

A fully adjustable seat, spacious cab, ergonomic controls and advanced music system all contribute to the ultimate working environment.

Safety at work

The ZX130-6 has been fitted with a high-spec rollover protective structure-compliant (ROPS) and centre pillar reinforced structure (CRES V) cab. The pressurised cab is designed to protect the operator from the penetration of dust and potential job site risks.

LEADING TECHNOLOGY

Hitachi takes the lead with a highly technological approach towards the development of its construction machinery. As a result, its excavators are designed to meet the ever-changing needs of its customers, with innovative features and exceptional capabilities.

Saving fuel and costs

Hydraulic loss is decreased by HIOS IV technology. It reduces the hydraulic oil returned to the tank due to the cooperative control of the pump and valve. This helps to lower fuel consumption by 7% in PWR mode with the same productivity.

User-friendly functionality

A large seven-inch multi-function LCD monitor provides a wide range of useful technical information. With multi-lingual support in up to 32 languages, it enables operators to check the machine’s status and settings at a glance.

Remote monitoring

Global e-Service allows owners to monitor their fleets remotely via Owner’s Site (24/7 online access) and ConSite (an automatic monthly report). These help to maximise efficiency, minimise downtime and improve overall performance

Fewer emissions

The after-treatment device consists of a diesel oxidation catalyst (DOC), urea mixing pipe, SCR system and silencer. This advanced technology helps to reduce emissions and noise levels.

Advanced audio system

The AM/FM radio is accessible from the monitor and an auxiliary socket – for devices such as MP3 players – is linked to the sound system. This choice of entertainment helps to provide an enjoyable – and productive – working environment.

REDUCING THE TOTAL COST OF OWNERSHIP

Hitachi has created the Support Chain after-sales programme to ensure optimum efficiency, as well as minimal downtime, reduced running costs and high resale values.

Global e-Service

Hitachi has developed two remote monitoring systems as part of its Global e-Service online application. Owner’s Site and ConSite are an integral part of the excavator, which sends operational data daily via GPRS or satellite to www.globaleservice.com. This allows immediate access to the Owner’s Site, and the vital information that is required for support on job sites.

Comparing the ratio of operating and non-operating hours helps to enhance efficiency. Effective management of maintenance programmes helps to maximise availability. Running costs can also be managed by analysing the fuel consumption. The location and movements of each machine are clearly displayed for essential planning.

An automatic service report – ConSite – sends a monthly email summarising the information from Global e-Service for each machine. This includes: daily working hours and fuel consumption data; statistics on the operating mode ratio, plus a comparison for fuel consumption/efficiency, and CO2 emissions.

Technical support

Each Hitachi service technician receives full technical training from HCME in Amsterdam. These sessions provide access to the same technical knowledge available within the Hitachi quality assurance departments and design centres. Technicians combine this global expertise with the local language and culture of the customer to provide the highest level of after-sales support.

Extended warranty and service contracts

Every new Hitachi Zaxis-6 model is covered by a full manufacturer’s warranty. For extra protection – due to severe working conditions or to minimise equipment repair costs – Hitachi dealers offer a unique extended warranty called HELP (Hitachi Extended Life Program) and comprehensive service contracts. These can help to optimise the performance of each machine, reduce downtime and ensure higher resale values.

Parts

Hitachi offers a wide range and a high availability of parts dispatched from the 53,000 m2 HCME European Parts Depot in The Netherlands.

• Hitachi Genuine Parts: allow machines to

work for longer, with lower running and

maintenance costs.

• Hitachi Select Parts and 2Genuine Parts: especially for older machines, they cost less, are of proven quality and come with the manufacturer’s warranty.

• Performance Parts: to cope with highly demanding conditions, they have been engineered for greater durability, better performance or longer life.

• Remanufactured components: offering an economically viable solution, they are the best option when preventative replacements are required.

Whatever the choice, the renowned quality of Hitachi construction machinery is assured.

BUILDING A BETTER FUTURE

Established in 1910, Hitachi, Ltd. was built upon a founding philosophy of making a positive contribution to society through technology. This is still the inspiration behind the Hitachi group’s reliable solutions that answer today’s challenges and help to create a better world.

Hitachi, Ltd. is now one of the world’s largest corporations, with a vast range of innovative products and services. These have been created to challenge convention, improve social infrastructure and contribute to a sustainable society

Hitachi Construction Machinery Co., Ltd. (HCM) was founded in 1970 as a subsidiary of Hitachi, Ltd. and has become one of the world’s largest construction equipment suppliers. A pioneer in producing hydraulic excavators, HCM also manufactures wheel loaders, rigid dump trucks, crawler cranes and special application machines at state-of-the-art facilities across the globe.

Incorporating advanced technology, Hitachi construction machinery has a reputation for the highest quality standards. Suitable for a wide range of industries, it is always hard at work around the world – helping to create infrastructure for a safe and comfortable way of living, developing natural resources and supporting disaster relief efforts.

Hitachi Zaxis excavators are renowned for being reliable, durable and versatile - capable of delivering the highest levels of productivity under the most challenging of conditions. They are designed to provide owners with a reduced total cost of ownership, and operators with the ultimate level of comfort and safety.